Cracks in concrete are quite a common sight. While some cracks are inevitable and not of great concern, some are signs of a larger underlying issue. In this article, we will explore the three main reasons why cracks form in concrete slabs, and the methods we use for managing them.

What is concrete?

What is concrete?Concrete is made up of three elements - cement, aggregate, and water. The aggregate in the mixture, usually sand (fine aggregate) or gravel (coarse aggregate), is combined with water via a binding agent - cement. Cement usually comprises of eight key ingredients (which include lime, silica, alumina, magnesia, iron oxide, calcium sulfate, sulfur trioxide, alkaline) that upon contact with water, produces a chemical reaction that hardens and solidifies, producing concrete.

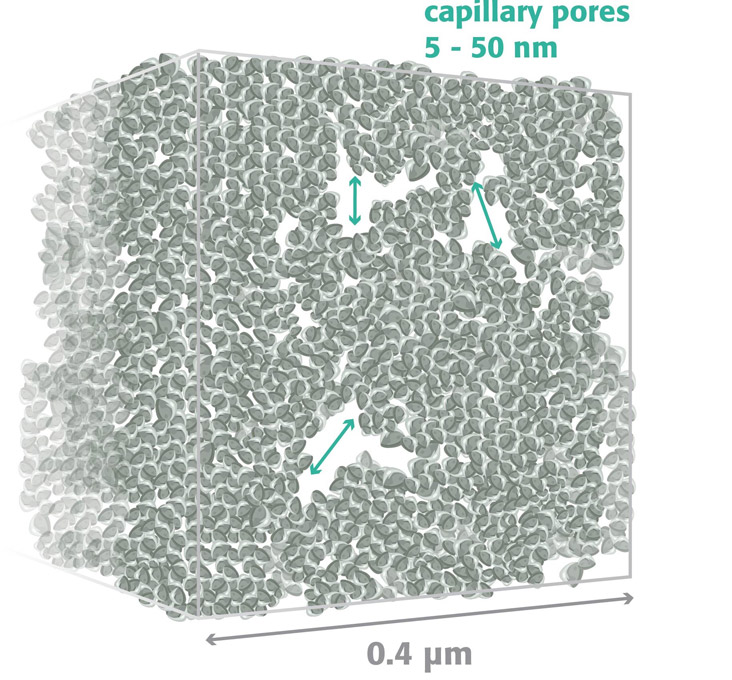

Concrete by nature is a porous material. This means that when it is curing, the water in the concrete takes up space. As concrete hardens, it loses its moisture through evaporation resulting in empty capillary pores and a slightly smaller shape. This process is known as drying shrinkage. Since concrete is very rigid, this shrinkage causes an increase in tensile stress, which may lead to, cracking, internal warping, or external deflection.

Concrete cracks when the drying shrinkage stresses exceed the tensile strength (amount of resistance a material can withstand when stretched or pulled) of the concrete. The spacing and size of cracks depend on the amount of shrinkage, degree of restraint, and amount and type of reinforcement. Drying shrinkage is the number one reason for cracks in concrete.

Control joints are most commonly installed in slab on grade concrete that is used in places such as driveways, pavements, house slabs, basement floors, and industrial spaces.

Control joints are generally fitted into the concrete during the finishing process and are placed so that the concrete forms a square or rectangular pattern. Control joints are used to manage the areas in the concrete where cracks may appear. This means that rather than allowing cracks to form at random, which will not be aesthetically pleasing, contractors use control joints to weaken slabs in specific areas and thereby regulating crack formations.

By installing control joints, it allows for movements within the concrete that may be caused by temperature changes or drying shrinkage. In terms of repairs, it is definitely easier and less costly to treat a control joint that numerous random cracks in the concrete.

Poor construction practices can also lead to the formation of cracks in concrete. Most of the time it comes down to:

The mistakes above basically undermine the strength of the concrete, resulting in it being prone to cracking under lower-than-expected tensile stress.

It is the duty of the contractor to follow all the proper application and safety procedures when handling concrete. With the appropriate onsite supervision and trained applicators, such practices can be avoided.

Mitigating Factors | Advantages of 752HP Floor System Solution |

Drying shrinkage | Provides high flexural strength. |

Tensile strength of concrete | Provides low shrinkage. |

Restrains | Uses macro synthetic fiber to reinforce concrete. |

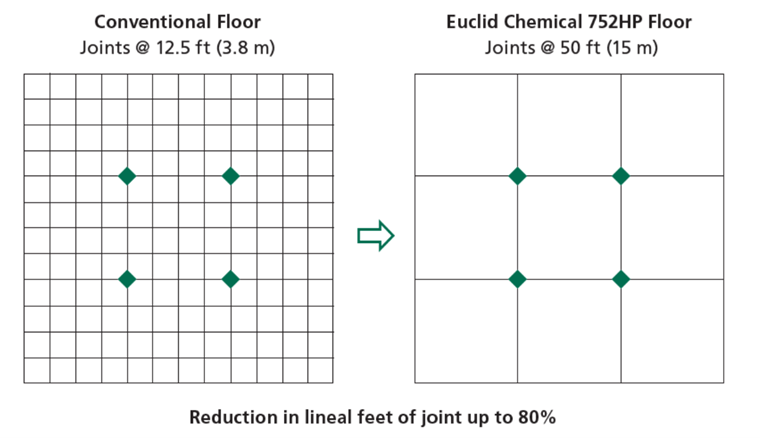

Controlled joints | Extends joint spacing. |

Construction practices | Improves serviceability – Tremco CPG employs skilled applicators and provides product warranty. |

Euclid’s 752HP proprietary flooring system is the perfect solution for managing cracks in slab-on-grade concrete. The key components of this system are:

CONEX is a powdered admixture used for compensation and total overall reduction of net shrinkage for Portland Cement concrete. Its functional mechanism is based on the formation of an expansive component. CONEX is an expansive Type G component, which produces a calcium hydroxide platelet crystal system, as specified in ACI 223.

TUF-STRAND SF is a patented polypropylene / polyethylene macro synthetic fibre successfully used to replace steel fibres, welded wire mesh and conventional reinforcing bars in a wide variety of applications. These fibres provide crack control, improved durability and load re-distribution. If shrinkage occurs, load transfer can still be maintained.

Euco QWIKjoint UVR is a joint filler that resists fading from ultraviolet light greater than any existing product. It is a fast-setting, semi-rigid polyurea, primarily used for filling construction and control joints in industrial and commercial concrete floors. It can also be used for crack and joint repairs in old floors. With the Euco QWIKjoint UVR, up to 15 m joint spacing (column line spacing) can be achieved instead of the conventional 3.8 m.

EUCO Diamond Hard is a unique blend of silicate and siliconate polymers that penetrate concrete surfaces and chemically react to provide an increase in surface density, durability, and abrasion resistance. The result is an attractive sheen on a dust-proof surface that is resistant to slips, skids and tire marks.

Learn more about the 752HP Floor System ››

Tremco CPG makes the process of selecting and installing the right flooring system simple and efficient. We offer a variety of tested, proven transition solutions that can accommodate any design, from standardised to highly specialised. All our concrete and flooring products provide the highest performance in adhesion, weatherability and durability.

Our expert team are on hand to help you in any current or upcoming project you may have, do get in touch with the team.

|

Need Support? |

Concrete, Waterproofing and Roofing, Infrastructure

The 5 Main Benefits of Crystalline Waterproofing

Concrete, Waterproofing and Roofing, Infrastructure

The 5 Main Benefits of Crystalline Waterproofing

Crystalline waterproofing is a process where the active ingredients in a crystalline product react with the free lime and moisture in the concrete to form crystals within the capillary...

Sign up for our newsletter

© 2024 Tremco Incorporated